A Practical Guide on Procurement Process for Improving Performance

Key takeaways

- The procurement function is much more than just the purchasing of goods or services.

- The procurement function involves the process of acquiring goods and services, with suppliers and buyers being the key players.

- The procurement strategy is affected by the business operating model, location of the business, financial budget, compliance management, and size of the business.

- The procurement lifecycle is made up of people, processes, and documentation.

- The procurement process is built on 5 principles – value addition, transparency, ethics, accountability and documentation, and uniformity and standardization.

- Using an AI-powered workflow automation tool like Cflow streamlines procurement and drives error-free, efficient operations.

These days, procurement is far more than just placing orders for supplies. It’s a make-or-break part of business where a single mistake can lead to wasted time, unnecessary costs, and damaged trust. Chasing vendor quotes, waiting on slow approvals buried in inboxes, and tracking down missing documents – manual procurement often feels like a race you can’t win, and it usually ends in missed deadlines, budget overruns, or compliance headaches.

Now, imagine a different picture: a procurement process that runs smoothly, every need is clearly defined, vendors are picked based on up-to-the-minute insights, approvals are done in moments, and every document is exactly where it should be. That’s the sweet spot procurement leaders are aiming for: spending less, getting more from suppliers, and knowing exactly what’s happening at every step.

Organizations with simplified procurement processes are 42% more likely to succeed in transformation initiatives than those with traditional, overly complex workflows. Conversely, overly complex approaches increase failure risk by 26%.

Procurement is evolving fast. With the right technology, it’s becoming a smart, strategic driver of value instead of just an operational task. In this blog, we’ll explore what that transformation looks like from the basics and step-by-step workflows to the models, challenges, and how automation can completely change the game.

Table of Contents

What is the Procurement Process?

The procurement process is the approach adopted by businesses to acquire goods and services. The procurement process landscape is undergoing a significant transformation driven by rapid technological transformation, evolving market dynamics, and ever-increasing demand for supply chain resilience and sustainability.

The procurement process now includes functions like gaining a deep understanding of business requirements, identifying quality and cost-effective vendors, and many such critical functions.

The globalization of business operations has widened the scope of the procurement function beyond the mere purchase of goods and services. The procurement process now includes functions like gaining a deep understanding of business requirements, identifying quality and cost-effective vendors and distribution channels, maintaining vendor relationships, and many more business-critical functions.

The procurement function in business is now part of the overall business strategy. A good procurement department will make sure that your company gets what it needs at the right price and on time. Having a streamlined procurement workflow is paramount to seamless purchase transactions and supply chain management. That’s why it’s important to have a solid understanding of how this works.

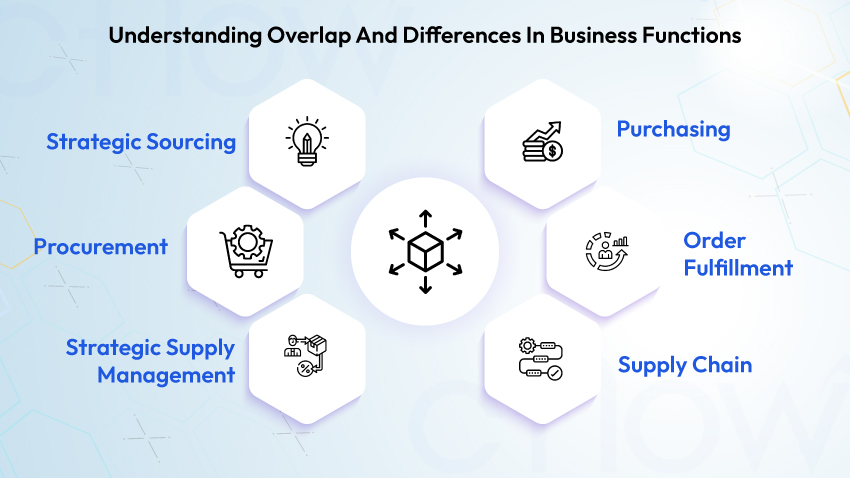

Procurement vs Purchasing vs Supply Chain: What’s the Difference?

Procurement, purchasing, and supply chain management are related functions, but they play distinct roles in how organizations acquire and deliver goods and services. Procurement is the strategic process of sourcing, negotiating, and managing suppliers to ensure the business gets the best value. It focuses on long-term relationships, compliance, and aligning purchases with business goals.

Purchasing is a subset of procurement. It deals with the transactional activities – issuing purchase orders, processing payments, and ensuring goods or services are received as specified. While procurement looks at the “why” and “from whom” to buy, purchasing focuses on the “how” and “when.”

Supply chain management is broader than both procurement and purchasing. It covers the entire flow of goods and services – from raw materials through manufacturing, distribution, and delivery to the end customer. Procurement is one critical step within this chain, ensuring the right inputs are sourced at the right quality and cost.

Types of Procurement Process

The procurement process can be divided into two phases: the buyer phase and the supplier phase. The buyer phase is the process of identifying potential suppliers and establishing a relationship with them. The supplier phase in the procurement workflow is focused on managing suppliers.

In this case, we are referring to a contract where you will buy certain products or services from one or more vendors on an ongoing basis. This is not necessarily the same as your “purchasing department” (if you have one). You should know that there are many different types of procurement processes out there, depending on how large your organization is and what type of goods or services you need to purchase.

For example, some organizations will have multiple departments in charge of different aspects of their purchasing process. The three common categories of the procurement process are direct, indirect, and services procurement.

1. Direct Procurement Process

Direct procurement deals with the purchase of the input (raw material) required for manufacturing the end product. The cost and efficiency of this type of procurement have a direct impact on the performance and profitability of the company. Any delay or block in the direct procurement process affects the business’s ability to manufacture the end product. Establishes long-term collaborative supplier relationships.

2. Indirect Procurement Process

Indirect procurement involves the purchase of input or services that are not directly related to the end product. Office supplies, maintenance services for equipment, and utilities are examples of indirect procurement. Indirect procurement process flow takes care of day-to-day operations and focuses on short-term relationships with the vendor.

3. Services Procurement Process

This type of procurement deals with procuring and managing a contingent workforce and consulting services. Software subscriptions and professional service purchases are examples of service procurement. Maintaining one-time, contractual relationships with suppliers is characteristic of the service procurement process.

Procurement Lifecycle (People, Process, Documentation)

The procurement lifecycle is built on three core elements – people, processes, and documentation – all working together to ensure transparency, efficiency, and compliance.

People

Stakeholders drive every stage of the procurement lifecycle, from identifying needs to approving purchases. These include procurement managers, finance teams, department heads, and end-users. Each has defined roles and responsibilities to keep the process aligned with business goals.

Processes

Processes are the structured workflows and rules that guide how procurement is carried out. This includes defining requirements, sourcing suppliers, negotiating contracts, placing orders, managing deliveries, and evaluating performance. A mapped process helps maintain consistency, avoid bottlenecks, and support cost control.

Documentation

Procurement generates a variety of documents – purchase requisitions, supplier contracts, purchase orders, invoices, and delivery receipts. Accurate documentation ensures compliance with internal policies, enables audits, and serves as a reference for future transactions or dispute resolution.

A well-structured procurement lifecycle gives businesses the control and visibility they need to make informed purchasing decisions, strengthen supplier relationships, and optimize spending.

Steps in the Procurement Process

A well-structured procurement process ensures timely delivery, cost efficiency, and compliance while maintaining the desired quality and supplier relationships.

1. Identification of Requirements

The procurement process begins with a clear understanding of business needs. This involves defining what needs to be procured, why it is required, the quantity, and the expected delivery timeline. Consulting all relevant stakeholders at this stage ensures alignment with operational and strategic goals.

2. Determining Requirement Specifications

Once needs are identified, detailed technical and functional specifications are drawn up. This step ensures suppliers understand exactly what is required, whether it’s for recurring purchases or new products. It also helps determine the best procurement method – competitive bidding, negotiated contracts, or a hybrid approach.

3. Sourcing Suppliers

The procurement team identifies potential suppliers through market research, supplier databases, and existing vendor lists. Vendors are evaluated based on quality, delivery speed, pricing, reliability, and industry reputation. For new purchases, at least three quotations are typically obtained or tenders published to encourage competitive offers.

4. Negotiating and Finalizing Terms

Shortlisted suppliers are invited to negotiate pricing, payment terms, warranties, delivery schedules, and service conditions. A transparent negotiation process ensures fairness and value. At this stage, businesses may decide whether to rely on a single vendor or diversify across multiple suppliers.

5. Raising Purchase Requisition and Order

After finalizing terms, a purchase requisition is prepared and routed for approval. Once approved, a purchase order (PO) is generated with complete details, including quantity, price, delivery date, and terms. A 3-way match – between requisition, supplier quote, and PO – is conducted to prevent errors.

6. Delivery of Purchase Order

The approved PO is shared with the supplier through agreed communication channels such as email, procurement portals, or in-person delivery. Both parties confirm the terms and timelines before moving forward.

7. Expediting Delivery

The procurement team tracks order progress and follows up with suppliers to ensure goods or services are delivered on schedule. Factoring in possible delays and creating contingency plans helps maintain continuity.

8. Supply, Inspection, and Acceptance

Upon delivery, the goods or services are inspected to verify they meet the agreed specifications and quality standards. Any deviations trigger returns, replacements, or corrective actions as per the contract. Acceptance of the order initiates the payment process.

9. Payment Processing

Before payment, all documentation, including the PO, supplier invoice, and delivery receipt, is verified. Discrepancies are resolved promptly to avoid disputes. Payment is released according to the agreed terms and within specified timelines to maintain good supplier relationships.

10. Documentation and Review

The entire procurement process is documented for auditing, compliance, and future reference. Periodic reviews help identify inefficiencies, improve supplier performance, and refine procurement strategies. Automation at this stage can significantly enhance accuracy and reduce administrative workload.

Choosing the Most Appropriate Procurement Method

Selecting the right procurement method is critical for balancing cost, quality, and timelines. The choice depends on the nature of goods or services, whether the requirement is one-off or recurring, bespoke or off-the-shelf, and the complexity and urgency of the procurement.

For example, purchasing a high-value item with a long lead time and complex specifications may not suit an open tender due to delays. Urgent requirements, such as a sudden surge in demand after an unforeseen event, may call for a negotiated approach to speed up timelines while retaining some price flexibility.

Key Procurement Methods and When to Use Them

Open Tendering – Invites all eligible suppliers to submit bids, ensuring maximum competition and transparency. Works best with well-defined specifications but can be time-consuming.

Sealed Bidding – Suppliers submit written bids, kept confidential until opening. Ensures fairness but requires precise, unambiguous requirements.

Negotiated Procurement – Direct discussions with one or more suppliers to agree on terms. Best for urgent, complex, or niche needs, but requires skilled negotiation.

Competitive Dialogue – Shortlisted suppliers engage in discussions to refine requirements before submitting proposals. Ideal for projects where specifications are not fully defined upfront.

Simplified Procedure – For low-value purchases, inviting selected suppliers for quick proposals reduces admin time but may limit competition.

Competitive Negotiation – Combines open competition with post-bid negotiations to improve offers. Useful when no clear winner emerges from initial bids.

Detailed Tendering & Bidding Workflow

Competitive bidding is one of the most widely used procurement methods for high-value or complex requirements. It ensures transparency, fairness, and value for money when selecting suppliers. Below is a step-by-step outline of how the process typically works:

Prepare Tender Documentation

Create clear, complete, and standardized tender documents outlining the project requirements, scope, timelines, and evaluation criteria. These documents act as the foundation for supplier proposals.

Screen and Evaluate Applicants

Review initial applications to remove those that do not meet the minimum eligibility or compliance requirements. This ensures only qualified suppliers proceed.

Approve Qualified Bidders

Formally approve a shortlist of suppliers who meet all technical, financial, and compliance standards to participate in the bidding process.

Issue the Request for Proposal (RFP) or Invitation to Bid (ITB)

Send the RFP or ITB to approved bidders. These documents provide detailed project specifications, submission guidelines, and deadlines.

Receive Bids

Collect bids from suppliers before the closing date. All bids must be securely stored and remain unopened until the official bid opening.

Evaluate Submitted Bids

Assess each bid based on cost, quality, compliance, delivery time, safety considerations, and any other defined criteria. Environmental impact and supplier experience may also be factored into the evaluation.

Approve the Preferred Bidder

Select the supplier that offers the best combination of value, quality, and compliance. High-value contracts may require additional senior management or board approval.

Award the Contract

Formally award the contract to the selected supplier, sign the agreement, and issue a notice of award. Contract terms should clearly outline deliverables, timelines, payment terms, and dispute resolution procedures.

End-to-end workflow automation

Build fully-customizable, no code process workflows in a jiffy.

Supply Chain Procurement

Supply chain procurement involves sourcing, selecting, and contracting with suppliers to acquire goods or services at the best value. A structured approach ensures cost efficiency, quality, and timely delivery.

1. Define Procurement Objectives

Identify the problem you’re solving, the outcomes you expect, and the budget and timeline for achieving them. Set measurable goals and determine the resources required so all stakeholders align before the process begins.

2. Create a Sourcing Plan

Research sourcing options based on your objectives. Assess potential benefits, costs, and timelines for each option. Identify the skills, tools, and team members needed to deliver results and set realistic expectations for project milestones.

3. Prepare the RFP or ITT

Draft a clear, detailed Request for Proposal (RFP) or Invitation to Tender (ITT) outlining your requirements, specifications, and evaluation criteria. Ensure the document is concise, easy to understand, and error-free to encourage strong supplier participation.

4. Receive and Track Supplier Bids

Collect proposals through a systematic process, ideally using an electronic bidding system for accuracy and record-keeping. Ensure all bids are complete and submitted within the set deadlines.

5. Evaluate Proposals

Assess bids using a predefined checklist based on cost, quality, capability, industry experience, and responsiveness. Engage an evaluation committee if the procurement is large or complex to ensure objective decision-making.

6. Select Supplier(s) and Negotiate Contracts

Choose the best-fit supplier(s) and negotiate terms covering pricing, delivery schedules, confidentiality, approval processes, and dispute resolution. Review the agreement carefully before signing to ensure clarity and completeness.

7. Award the Contract and Finalize Documentation

Sign the contract, communicate the award to the supplier, and comply with any regulatory requirements, such as public notices or internal reporting. Maintain proper documentation for compliance and future reference.

Procurement Workflow Models

A streamlined procurement workflow is mostly built on a procurement model. A procurement model is made up of a series of steps that a business follows to procure goods or services. The levels of hierarchy, control, and decision-making are described in the procurement model.

Factors like geographical boundaries and the number of departments and divisions in the organization influence the choice of procurement model. Depending on the control centre in the procurement process, procurement models are of three types: local, centralized, and hybrid models.

Local Procurement Model

In this procurement model, the decision-making is made at the local or department level. All procurement decisions are taken by the local department, which has a better understanding of the department’s needs. Local procurement processes may often lead to uncontrolled spending, which will be out of sync with the overall organizational budget.

Centralized Procurement Model

As the name suggests, in a centralized procurement model, key decisions are taken by central purchase management. The approval process and the procurement rules are governed by the central leadership. The centralized procurement model intends to align purchase decisions with the overall organizational budget and spending.

Bulk purchases have a greater price negotiation advantage when done through the centralized model. However, increased bureaucracy and the risk of not meeting the unique requirements of individual departments are disadvantages of this procurement model.

Hybrid Model

This is a combination of a centralized and local procurement model. Some purchases are localized while others are central. The advantages of local and centralized models are combined in the hybrid model.

Principles of Effective Procurement

The supply chain of a business starts with the procurement process. An effective procurement process sets the tone for the entire supply chain. The profit margins and quality of goods and services both depend on the procurement process. A cost-effective and efficient procurement process is built on 5 principles.

1. Value addition

The procurement process must be value-driven. Procurement decisions must focus on deriving value for money, rather than low costs alone. Compromise on the quality of inputs (raw materials) has a cascading effect on the final output of the company.

2. Transparency

The vendor selection process must be free from bias, which ensures a fair playing field for all the suppliers. Transparency in the vendor selection process ensures that the buyer gets maximum value for the investment.

3. Ethics

Vendor selection in the procurement process may be done through bidding tenders or direct purchases. The buyer must ensure high ethical standards and follow a transparent vendor selection process so that the quality and value of the purchase are maintained.

4. Accountability and Documentation

All the stakeholders in the procurement process must be accountable for their actions. Clear documentation of each procurement stage helps in the review and refinement of the procurement lifecycle.

5. Uniformity and standardization

Uniformity and consistency must be ensured at every stage of the procurement process. Following the standard procurement guidelines provides all players with equal opportunities to grow.

Key Procurement KPIs

The procurement process, like any other business process, needs to be evaluated for performance and efficiency. Procurement key performance indicators (KPIs) help in evaluating the efficiency, effectiveness, and performance standards of the procurement strategy and process.

Procurement managers use specific KPIs to measure the effectiveness of procurement workflows. KPIs may be classified as quantitative and qualitative KPIs. The former type can be represented as a number, while the latter cannot be represented numerically.

The following KPIs help assess the performance standard and efficiency of the procurement process:

| KPI Category | KPI | Description |

|---|---|---|

| Supplier KPIs | Supplier Availability | The measure of the responsiveness and availability of the supplier for urgent and emergency orders. |

| Quality, Accuracy, and Compliance | Verifies whether the vendor maintains quality and compliance with requirements. Errors or defects increase costs and waste time. | |

| Several Suppliers | Indicates whether the business is over-dependent on a small group of suppliers. | |

| Supplier Capacity | Helps evaluate the capability of suppliers in catering to bulk orders. | |

| Purchase Order KPIs | Order Cycle Time | Measures how long procurement takes or the turnaround time for one order cycle. Useful for evaluating suppliers suited for urgent supplies. |

| Cost of Purchase | Tracks the cost incurred to process each purchase and helps identify internal procurement costs. | |

| Lead Time | The time taken from when the purchase order is placed to when items are delivered. | |

| Return on Investment (ROI) KPIs | Savings on Cost | Measures the cost savings achieved by the company through the procurement process. |

| Total ROI | Calculates the overall ROI of the entire procurement process. |

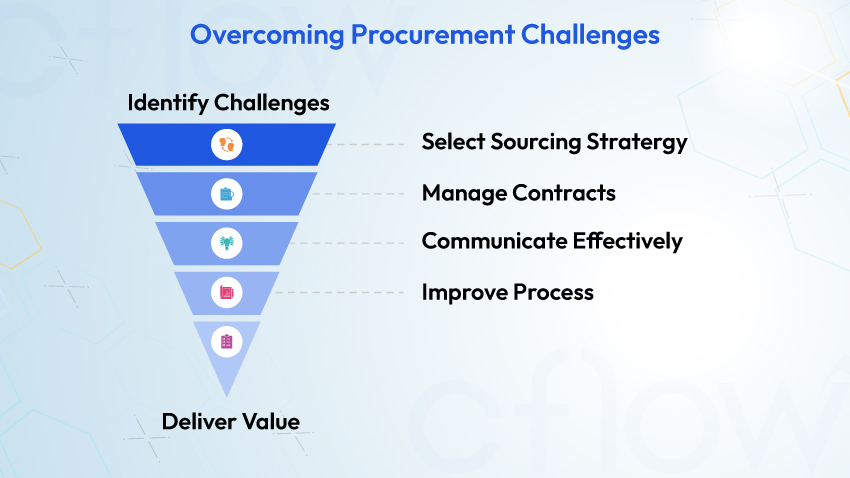

Challenges Faced in the Procurement Process

Improving internal processes enables you to move beyond obstacles and deliver value. The following are some of the typical challenges faced in the procurement process

1. Selecting the Right Sourcing Strategy

Choosing the right sourcing strategy requires a clear understanding of your business needs and the type of procurement involved. The first step is to determine whether you need suppliers for all or only part of your product or service requirements. This decision will help narrow down your procurement options.

In many cases, organizations prefer sourcing from suppliers they already have established relationships. However, there are situations where sourcing from multiple suppliers may be beneficial:

- To secure competitive pricing for high-quality products and services.

- To meet regulatory requirements related to fair trade practices (e.g., using multiple suppliers for similar products).

2. Timely Contract and Vendor Risk Management

Contract management plays a critical role in procurement, enabling organizations to manage risks associated with contracts and vendors while ensuring compliance with internal policies and regulations. An effective contract management plan should include:

- Clearly defined terms and conditions.

- Comprehensive contract administration services.

Contract administration should cover:

- Regular reporting and monitoring of compliance with contractual terms, including supplier financial reports (as required under the Financial Administration Act 2004).

- Ensuring all suppliers meet their contractual obligations.

- Resolving disputes through established dispute resolution processes.

3. Proper Communication with Stakeholders

Clear, consistent communication is essential throughout the procurement process. It should always be two-way, with the buyer receptive to updates or changes from the supplier.

Buyers and suppliers must understand each other’s needs and requirements to build a strong, long-term working relationship that can last beyond a single project or transaction.

4. Managing and Controlling Procurement for Maximum Value

To maximize value from procurement spending, organizations should focus on:

- Effective management and oversight of procurement activities.

- Strong control mechanisms to prevent waste and inefficiencies.

- Ongoing process improvement to address challenges proactively.

- Continuous improvement initiatives to adapt to changing business needs.

The most effective way to overcome procurement challenges is by improving internal processes. This enables organizations to move past obstacles, deliver greater value, and support more efficient operations.

How to Optimize Procurement

Optimizing procurement is about building a process that is consistent, transparent, and adaptable to changing business needs. By refining workflows, strengthening supplier relationships, and tightening controls, businesses can reduce costs, improve quality, and achieve greater value from every purchase.

Establish a Clear Approval Hierarchy – Define who is responsible for approvals at each stage of the procurement process. This reduces delays, ensures accountability, and aligns purchasing decisions with organizational goals.

Maintain Transparent Supplier Relationships – Engage with vendors openly and maintain clear communication channels. Regular reviews of supplier performance help identify areas for improvement and ensure expectations are met.

Frame Contracts Carefully – Draft contracts with precise terms, conditions, and dispute resolution clauses. This minimizes misunderstandings and protects both parties in case of conflicts.

Use Proactive Inventory Management: Maintain optimal stock levels to avoid last-minute purchases and rushed supplier selection. Accurate demand forecasting reduces costs and prevents supply interruptions.

5. Involve Stakeholders in Continuous Improvement – Gather feedback from all stakeholders – finance, operations, legal, and end-users – after each procurement cycle. This collaborative approach helps identify bottlenecks and refine processes.

Ensure Ethical and Fair Practices

Follow procurement principles that promote fairness, equal opportunity, and compliance with regulations. Avoid conflicts of interest to maintain credibility and trust.

Improve Sourcing Strategies: Assess whether single-sourcing, multi-sourcing, or global sourcing offers the best value for a given requirement. This decision should be based on cost, quality, and risk considerations.

Strengthen Contract and Vendor Risk Management: Develop a contract management plan that includes compliance tracking, regular reporting, and structured dispute resolution. Monitor vendor performance closely to mitigate risks.

Keep Communication Two-Way: Encourage open dialogue between buyers and suppliers. Understanding each other’s needs builds stronger, long-term partnerships that benefit both sides.

Commit to Ongoing Process Reviews: Regularly evaluate procurement workflows against KPIs such as cost savings, lead time, and supplier performance. Use these insights to drive consistent improvement.

How Technology & AI Enhance Procurement

50% of early adopters – organizations piloting or deploying Generative AI in procurement reported their ROI had doubled, and some advanced deployments saw returns of 5× or more compared to traditional methods.

Technology and AI are transforming procurement from a manual, paper-driven process into a highly efficient, data-driven function. By integrating automation, analytics, and AI-powered tools, procurement teams can move beyond transactional tasks to strategic decision-making.

Artificial Intelligence (AI) for Smarter Decisions

AI analyzes vast amounts of procurement data – supplier history, market trends, contract performance, and provides predictive insights. This helps identify the best suppliers, anticipate price fluctuations, and forecast demand with greater accuracy. AI-powered recommendation engines also assist in optimizing sourcing strategies.

Machine Learning (ML) for Continuous Improvement

ML algorithms learn from past procurement transactions, approval patterns, and supplier performance. Over time, they become better at predicting risks, identifying cost-saving opportunities, and recommending process improvements, reducing reliance on manual judgment.

Robotic Process Automation (RPA) for Repetitive Tasks

RPA automates routine activities like purchase order creation, invoice matching, and vendor data updates. This not only speeds up procurement cycles but also minimizes human error and frees staff for more strategic work.

Data Analytics for Supplier Performance Monitoring

Advanced analytics track supplier KPIs in real time, such as on-time delivery rates, defect percentages, and contract compliance. This enables procurement managers to make evidence-based supplier decisions rather than relying on anecdotal feedback.

Cloud-Based Procurement Platforms for Centralization

Modern cloud solutions centralize all procurement activities – RFQs, approvals, contracts – into one secure platform. Teams can collaborate seamlessly across locations, ensure compliance, and maintain full visibility over spend.

Integration with ERP and Supply Chain Systems

Procurement technology integrates directly with ERP and supply chain platforms, ensuring that purchase data, inventory levels, and supplier updates flow automatically across systems. This eliminates data silos and improves supply chain coordination.

Blockchain for Secure Transactions

Blockchain adds transparency and security to procurement by creating tamper-proof records of transactions and contracts. This reduces the risk of fraud and builds trust between buyers and suppliers.

How Procurement and Finance Work Together

A strong link between procurement and finance turns purchasing from a cost center into a value driver. Here’s how the partnership works in practice:

Finance Sets the Guardrails, Procurement Plays Within Them – Finance defines budgets, spend thresholds, and cash flow priorities. Procurement uses these parameters to negotiate supplier contracts that meet both operational needs and financial limits.

Procurement Sources, Finance Pays – But Both Approve – Procurement identifies the right vendors and negotiates terms. Finance validates invoices, ensures correct coding, and processes payments, closing the loop with full accountability.

Compliance Isn’t Just a Finance Job – Finance manages audit readiness, but procurement ensures every purchase meets policy, regulatory, and ethical requirements before it even reaches the payment stage.

Data Flows Both Ways – Procurement shares supplier performance, lead time, and pricing trends. Finance shares budget variance reports and payment history. Together, they create actionable insights for better negotiations and forecasting.

Cash Flow Meets Supplier Relationships – Finance balances payment timing for liquidity; procurement aligns with suppliers on terms that maintain trust without straining working capital.

When these functions share systems, automate workflows, and communicate continuously, they eliminate bottlenecks, reduce costs, and make spend management a strategic advantage instead of an operational headache.

Benefits of Strong Supplier Relationships

Building strong supplier relationships is more than just maintaining good communication – it’s about creating partnerships that drive efficiency, reduce costs, and ensure long-term supply stability. When procurement teams work closely with suppliers, the benefits extend across the entire supply chain.

1. Consistent Quality and Reliability – Suppliers that trust your business are more likely to prioritize your orders, maintain high-quality standards, and meet delivery schedules, reducing the risk of production delays.

2. Better Pricing and Value – Long-term relationships open the door to favorable pricing, volume discounts, and added value services. Suppliers are more willing to negotiate competitive terms when they see you as a dependable partner.

3. Increased Supply Chain Resilience – Strong relationships provide better access to scarce materials during market shortages. Reliable suppliers will often fulfill commitments to loyal customers first, helping you maintain operations under pressure.

4. Faster Problem Resolution – When issues arise – from late shipments to product defects – trusted suppliers are more responsive and collaborative in finding quick, workable solutions.

5. Opportunities for Innovation – Suppliers often have insights into new materials, technologies, and processes. A good relationship encourages them to share innovations that can improve your products or reduce your costs.

6. Improved Compliance and Risk Management – Close partnerships make it easier to align on compliance requirements, ethical standards, and sustainability goals, reducing regulatory and reputational risks.

7. Long-Term Strategic Advantage – By building mutual trust and shared objectives, you create a network of suppliers who are invested in your success – a competitive edge that’s hard for competitors to replicate.

Automating the Procurement Process

According to the annual Gartner survey of procurement priorities, 1 in every 4 procurement leaders focuses exclusively on category strategies and category management. Also, another 24% of the procurement leaders focus on identifying and eliminating potential supplier risk.

So, even if automating your procurement functions can be helpful, you need to have an in-depth understanding of the existing procurement workflow. The automation potential of procurement tasks can be determined based on the following points:

- Tasks with high potential for cost savings.

- Tasks where the benefits can outweigh the costs.

- Complex processes that prove to be costly and cumbersome to automate should not be chosen.

- Simple, repetitive tasks can be automated easily.

Based on the above points, we have identified the following four procurement processes that can be automated effectively. Purchase Requisitions Purchase requisitions are raised internally by employees requesting approval for a purchase. Purchase requisitions typically go through several levels of approval, which may lead to delays and bottlenecks when done manually.

Discover how automation can transform your procurement workflows. Explore Our Procurement Automation Solutions.

Automating the approval of purchase requisitions helps accelerate the requisition approval process. Purchase Order Processing: Processing purchase orders is a repetitive and relatively simple process that can be automated effectively. This process is executed frequently by organizations. Invoice Approvals Vendor invoices go through internal approval before the finance department credits the payment to the supplier.

Automating the invoice approval process enables faster and easier approval of invoices. Automation also enables anytime, anywhere payment of invoices. Vendor Management: Identifying and vetting prospective vendors before they are included in an approved vendors list happens through a sequence of approvals.

This process can be automated for efficient vendor management. The choice of workflow automation software is critical for successful automation. With so many tools out there, Cflow is a smart choice.

Streamlining Procurement with Cflow’s AI-Powered Workflow Automation

Cflow is a powerful cloud BPM software that can automate key business workflows within minutes. Your procurement workflows will be much more efficient and streamlined when automated with an AI-powered workflow solution like Cflow.

It is a no-code workflow solution that even a non-technical person can use to build forms and configure workflows. The easy-to-use visual workflow builder helps build procurement workflows quickly and effortlessly.

On a final note, Procurement is a strategic function of an organization, and its objective is to provide value-added services to the organization. To achieve this objective, the procurement function and processes must be well structured and designed.

Moreover, workflow automation enables businesses to stay on top of the changes in the supply markets and market intelligence data. Cflow enables end-to-end procurement process automation through a powerful cloud-based BPM platform. Try Cflow today to experience the benefits of procurement process automation.

Frequently Asked Questions

1. What is the procurement process?

The procurement process is the structured workflow a business uses to identify needs, source suppliers, negotiate contracts, place orders, manage delivery, process payments, and conduct reviews. It ensures efficiency, transparency, and alignment with business goals.

2. What are the 5 stages of the procurement process?

A common breakdown includes:

- Need Identification

- Supplier Sourcing & Evaluation

- Contracting / Negotiation

- Order Placement & Delivery

- Receipt, Payment & Review

3. What are the 4 types of procurement?

- Direct Procurement – raw materials and goods for production

- Indirect Procurement – non-production items like office supplies

- Services Procurement – contracting services such as consulting or staffing

- Strategic/Digital Procurement – emerging category based on business model

4. What is an RFQ in procurement?

RFQ stands for Request for Quotation. It’s a document sent to suppliers to request pricing and terms for specific goods or services. Businesses use it to compare offers and select the best value supplier.

5. What is PO in procurement?

PO means Purchase Order. It’s a formal document issued by the buyer to the supplier detailing quantities, specifications, delivery dates, and agreed prices. It acts as both a legal contract and an audit trail.

What should you do next?

Thanks for reading till the end. Here are 3 ways we can help you automate your business:

Do better workflow automation with Cflow

Create workflows with multiple steps, parallel reviewals. auto approvals, public forms, etc. to save time and cost.

Talk to a workflow expert

Get a 30-min. free consultation with our Workflow expert to optimize your daily tasks.

Get smarter with our workflow resources

Explore our workflow automation blogs, ebooks, and other resources to master workflow automation.