Understanding Open Purchase Orders: Everything You Need to Know

Key takeaways

- An open purchase order is a pending transaction that remains active until fully delivered and billed.

- Poorly managed open POs can distort budgets, delay audits, and impact vendor relationships.

- Workflow automation helps businesses track, review, and close open POs faster and with more accuracy.

- Cflow enables seamless open PO management through automation, integration, and real-time analytics.

Table of Contents

What are Open Purchase Orders?

An open purchase order is a fundamental element of procurement operations. It refers to a formal document issued by a buyer to a vendor that remains active until all goods or services have been delivered and invoiced. It serves as a financial commitment and an operational agreement. Unlike closed purchase orders, which are complete and reconciled, open purchase orders are in progress and require ongoing tracking.

Understanding how open purchase orders work is essential for ensuring procurement transparency, inventory control, and financial accuracy. In this blog, we’ll explore what an open purchase order means in procurement, how to manage open POs in ERP systems, common challenges, financial implications, best practices, and how automation tools like Cflow streamline the entire lifecycle.

Why are Open Purchase Orders Needed?

Open purchase orders are more than just pending transactions—they act as essential control mechanisms in procurement and finance. Businesses issue POs to formalize their intent to purchase goods or services, but keeping them open until fulfillment ensures traceability, accountability, and clarity across departments.

One of the main reasons open POs are needed is to track outstanding commitments. When a PO is open, it signifies that the budget has been allocated for a purchase, but the expense has not yet been fully realized. This helps financial teams manage encumbered funds and avoid overspending. Without this visibility, businesses might mistakenly assume they have more funds available than they actually do.

Open POs also act as a reference point for supplier performance. They enable procurement teams to compare what was ordered versus what was delivered. If deliveries are delayed, incomplete, or non-compliant with the original order, the open PO serves as an official record to resolve disputes or enforce vendor accountability.

From a supply chain perspective, open purchase orders are critical for demand planning and inventory forecasting. For example, manufacturing companies rely on open PO data to schedule production runs based on the expected arrival of raw materials. Without knowing what’s en route or pending, they risk halting production due to shortages or wasting warehouse space on overstock.

In audit and compliance workflows, open POs ensure a verifiable trail of purchasing activity. They prove that goods were ordered with appropriate authorization and allow auditors to trace the lifecycle of a transaction, from request to receipt to payment. Open POs help mitigate risks related to fraud, unauthorized purchases, or payment errors.

Finally, in organizations with multiple stakeholders or decentralized purchasing, open POs improve interdepartmental coordination. Procurement, finance, warehouse, and project teams can access the same data to understand what items are pending, when they’re expected, and whether they align with project deadlines or budget plans.

In summary, open purchase orders provide clarity in purchasing, ensure financial discipline, support vendor management, and drive operational efficiency. Their value goes far beyond tracking—they are essential for maintaining control across the entire procurement lifecycle.

What is an open purchase order in procurement?

An open purchase order in procurement is a transaction that has been initiated but not yet completed. It contains all relevant details such as item descriptions, quantities, delivery timelines, and payment terms. The PO is considered open until the supplier fulfills the request and the company has processed the final invoice.

For example, a manufacturer might issue a PO for 1,000 units of raw material. If only 600 units have been delivered and billed, the PO remains open. This ongoing status is important because it indicates an active financial and inventory obligation.

Procurement teams use open purchase orders to plan purchases, control spending, and ensure vendors deliver on time. They also help teams avoid placing redundant orders when existing POs are still in progress.

How to Manage Open Purchase Orders in ERP Systems

Managing open purchase orders through ERP systems requires more than just data entry. It involves configuring workflows, assigning responsibilities, and enabling automation to ensure real-time visibility into the status of every purchase order. When done well, this process improves control, enhances supplier performance, and prevents procurement delays.

The starting point is to ensure that the ERP system reflects the most current data. This includes delivery acknowledgments, partial or full receipts, and invoicing updates. If these actions are not recorded promptly, a purchase order may remain open in the system even when the transaction has been fulfilled. To avoid this, companies should integrate the purchase order process with inventory and accounts payable modules, enabling automatic status changes once deliveries or payments are made.

Assigning clear ownership of each purchase order is another important step. When individual responsibility is not defined, follow-ups with vendors may be delayed or missed altogether. By assigning a procurement lead or category manager to each PO, organizations can ensure that someone is accountable for its progress and closure. This also makes it easier to identify bottlenecks when POs are overdue or incomplete.

Automation capabilities within ERP systems can significantly streamline PO tracking. For example, configure the system to send alerts when a PO has been open for more than 30 or 60 days, or when it lacks a corresponding goods receipt or invoice. These alerts serve as proactive reminders for procurement and finance teams to investigate and resolve delays. Aging reports that categorize open POs by duration can also help prioritize action.

Creating a workflow to handle changes to open purchase orders is equally important. Sometimes, items are canceled, delivery timelines change, or prices are renegotiated. ERP systems should allow for controlled modifications with proper authorization, so the updated PO reflects the latest agreement. Without such controls, misalignment between what was ordered and what was received can result in invoice discrepancies and financial reporting errors.

For large organizations with multiple locations or high PO volume, standardizing the process for reviewing and closing open POs ensures consistency. Establish a policy that defines when a PO should be considered stale and closed if no activity occurs within a set period. Some companies close POs automatically after 90 days of inactivity, subject to the procurement manager’s review. These rules help keep the system clean and make reporting more accurate.

Lastly, user adoption is essential. The best ERP systems offer excellent features, but if procurement, warehouse, and finance teams are not properly trained, data gaps and delays are inevitable. Regular user training, clearly documented processes, and system audits ensure that all teams know how to update PO statuses, confirm deliveries, and flag issues.

In conclusion, managing open purchase orders in ERP systems requires a structured approach that combines automation, accountability, and real-time data sharing. By leveraging ERP capabilities effectively, organizations can reduce manual errors, shorten procurement cycles, and maintain better control over vendor performance and financial commitments.

Common Issues with Open Purchase Orders that Disrupt Operations

Open purchase orders that are not monitored regularly create operational inefficiencies. One major issue is the accumulation of aging POs that have not been closed due to a lack of follow-up or incomplete deliveries. These outdated records clutter procurement databases and misrepresent the company’s current obligations.

Another problem is duplicate orders. When teams are unaware of existing open POs, they may unknowingly place a new order for the same items, resulting in excess inventory or wasted budget.

Inaccurate or delayed reporting is also a concern. During audits, open POs without matching deliveries or invoices raise compliance questions and prolong the audit cycle. Moreover, vendors may deliver incorrect quantities or fail to follow through if communication is not proactive.

All of these issues stem from one root cause: the lack of a consistent and automated tracking system for purchase orders.

Open purchase order vs Closed Purchase order: Know the Difference

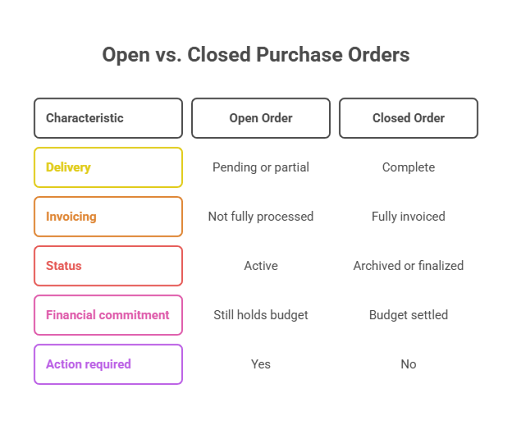

Distinguishing between open and closed purchase orders is critical for clean recordkeeping and budgeting. Open POs are active documents awaiting full or partial fulfillment. Closed POs are finalized—goods have been received, invoices matched, and payments processed.

Here’s how they differ:

Managing this lifecycle properly ensures accuracy in forecasting, vendor communication, and financial reporting.

Open PO follow-up Process for Vendors: a Workflow Approach

A structured vendor follow-up process is essential for managing open POs effectively. The first step is setting up alerts once the delivery date has passed or partial fulfillment has occurred. These alerts should trigger follow-up actions automatically through your procurement system.

Maintain a digital log of communication with the vendor, including updates on expected delivery and reasons for delays. This log provides a paper trail in case of disputes or performance reviews.

Create an escalation policy where unresolved POs are brought to the attention of senior procurement or vendor management teams. If a vendor cannot fulfill the remaining quantity, you should have a clear policy for closing or modifying the PO.

This proactive approach helps vendors stay aligned with expectations and keeps the purchase order lifecycle moving forward without unnecessary delays.

Reporting open purchase orders in accounts payable

Accounts payable teams rely on accurate open PO data to ensure invoices are paid on time and budgets are not exceeded. When open POs are not regularly reconciled, the finance team may either overstate or understate liabilities.

Unmatched invoices and open POs can create bottlenecks in payment processing, resulting in missed early payment discounts or late fees. This can damage vendor relationships and add to the cost of doing business.

To avoid this, companies should implement automated reporting tools that present open PO data in real time. Dashboards showing aging POs, matched vs. unmatched invoices, and pending approvals enable faster payment processing and better financial oversight.

Open Purchase Order Meaning in the Supply Chain Context

In the supply chain, open purchase orders act as a reference point for incoming goods and scheduling. They help warehouse managers plan for incoming shipments, allocate space, and prepare logistics for unloading and storage.

From a production standpoint, open POs are used to estimate when raw materials or components will arrive. This information is crucial for production planning and inventory turnover. If POs remain open longer than expected, it can stall manufacturing timelines and cause order delays.

Connecting open PO data with your supply chain dashboard ensures that planning, procurement, and logistics teams are always aligned on what’s expected and when.

Automating Open Purchase Order Review and Closure with Cflow

Manually tracking and managing open purchase orders across multiple departments and vendors is not only inefficient but also error-prone. This is where automation becomes a game-changer. Cflow, a no-code workflow automation platform, offers a tailored solution to manage the entire purchase order lifecycle—from issuance to closure. By automating the review and follow-up process, Cflow helps procurement and finance teams maintain tighter control over open POs, reduce processing time, and improve vendor collaboration.

Key features of Cflow

Cflow is designed to simplify complex workflows without the need for coding expertise. It offers a range of features that directly address the pain points in managing open purchase orders:

Visual Workflow Builder

Users can create custom workflows for the PO lifecycle using a drag-and-drop interface. From approval hierarchies to vendor communication triggers, everything can be visually mapped and automated.

Automated Alerts and Reminders

Cflow can be configured to send timely reminders when a purchase order remains open beyond a set duration or lacks invoice and delivery updates. This ensures proactive follow-up without manual intervention.

Vendor Portal Integration

Vendors can be given limited access to view PO statuses, confirm deliveries, and upload invoices, improving communication and reducing back-and-forth emails.

Approval Routing

Cflow routes open POs to the appropriate managers or stakeholders based on predefined rules. Whether it’s a pending invoice match or a delivery delay, the right person is notified instantly.

Audit Logs and Reporting

All actions taken on a PO—modifications, approvals, escalations—are logged automatically. This ensures transparency and simplifies internal audits.

ERP and Accounting Integration

Cflow integrates easily with leading ERP systems and accounting software, enabling seamless data flow between procurement, finance, and inventory functions.

Mobile Accessibility

With its mobile-compatible interface, users can manage purchase orders on the go. This supports faster decisions and avoids delays due to unavailability.

These features work together to create a highly transparent and accountable purchase order management environment, where nothing slips through the cracks.

The Cflow Advantage

What sets Cflow apart is its ability to combine ease of use with deep functionality. While traditional ERP systems often require technical support and rigid configuration, Cflow is flexible, intuitive, and built for non-technical users. It empowers procurement and finance teams to take ownership of workflows without relying on IT for every change.

Cflow significantly reduces the time spent on manual follow-ups and reconciliations. Teams can shift their focus from tracking transactions to managing vendor performance and optimizing procurement strategies. The platform’s smart alerts ensure that no open PO is overlooked, while analytics provide insights into trends like supplier delays or frequent discrepancies between orders and invoices.

For organizations with decentralized procurement or multiple vendors, Cflow creates a centralized view of all open POs. This improves communication across departments and ensures consistency in how purchase orders are handled. By eliminating manual errors and improving compliance, Cflow helps businesses build more reliable financial and operational systems.

In essence, Cflow is not just a tool—it is a strategic enabler that transforms open PO management from a tedious administrative task into a streamlined, insight-driven process. Whether you’re looking to close aging POs, accelerate invoice matching, or reduce procurement cycle times, Cflow offers the automation needed to meet those goals effectively.

How open POs Impact Inventory and Budgeting

Open purchase orders play a significant role in inventory planning and financial forecasting. When a PO is open, it indicates that items are on the way. Inventory systems use this information to avoid over-ordering and optimize warehouse space.

Financially, open POs represent committed spend that hasn’t been realized. If these commitments aren’t properly recorded, they can distort available budget calculations. This creates confusion when planning for new expenditures or justifying financial allocations.

Organizations must regularly review and update open PO statuses to maintain accurate records across procurement, inventory, and finance departments.

End-to-end workflow automation

Build fully-customizable, no code process workflows in a jiffy.

Comparative Insights

Region | Key Procurement Cost Characteristics |

North America | High volatility due to inflation and global shipping; rising input costs noted. |

Europe | Strong spend influence and efficient procurement practices among top performers. |

Global Averages | Typical procurement cost: 1–2% of spend; best-in-class: below 1%. |

Asia & Latin America | Lower base costs but higher risk from supply chain inefficiencies and imports. |

Cflow for Reducing Procurement Costs Through Automation

Cflow is a no-code workflow automation platform that helps organizations reduce procurement costs by digitizing and streamlining every step of the process. It eliminates inefficiencies, improves transparency, and enables faster decision-making while reducing dependency on manual tasks and disconnected systems.

By using Cflow, businesses gain complete control over their procurement lifecycle—from requisition to approval, supplier management, and invoice processing. This results in reduced administrative burden, improved process compliance, and greater accountability at every stage.

Key Features That Support Cost Reduction:

- Visual Workflow Builder: Enables teams to create and customize procurement workflows without coding, reducing reliance on IT and improving adaptability.

- Automated Purchase Approvals: Eliminates delays and errors by routing purchase requests based on user roles, budget thresholds, and categories.

- Real-Time Budget Tracking: Allows procurement and finance teams to monitor budget utilization and prevent overspending before it occurs.

- OCR and Three-Way Matching: Digitally extracts data from invoices, matches it with POs and delivery receipts to ensure payment accuracy and prevent duplicates.

- Supplier Database and Rating: Stores vendor performance metrics to support better decision-making and supplier negotiations.

- Seamless Integration: Works with ERPs, finance systems, and document management platforms to create a unified procurement ecosystem.

Cflow Advantage in Procurement Cost Management:

Reduction in Manual Errors

Automated workflows reduce human error, duplicate orders, and non-compliant purchases.

Faster Cycle Times

Automating procurement processes accelerates PO creation, approval, and payment timelines.

Lower Administrative Overhead

Minimizes paperwork and communication delays across departments.

Better Spend Visibility

Dashboards and reports help procurement leaders identify cost drivers and control them proactively.

Improved Policy Enforcement

Ensures that procurement follows organizational policies and approval hierarchies.

Cflow empowers procurement teams with the flexibility to adapt, scale, and optimize cost structures without disrupting day-to-day operations. Whether you’re a growing company or an enterprise seeking tighter cost control, Cflow delivers a robust, easy-to-use solution tailored for procurement excellence.

Final Thoughts

Procurement costs are often underestimated, yet they can represent a significant portion of a company’s operational expenditure. When left unmanaged, these costs quietly erode profit margins and create inefficiencies across departments. As procurement functions become more strategic, tracking and controlling costs becomes not just necessary, but essential to sustaining long-term business health.

Understanding what makes up procurement costs—from purchase prices to administrative overhead—enables organizations to take a holistic view of their sourcing activities. This comprehensive insight allows procurement teams to shift from reactive purchasing to proactive planning, aligning procurement goals with broader financial objectives.

Cost optimization, however, requires more than one-off cost-cutting initiatives. It requires investment in process automation, clear policies, real-time visibility, and continuous supplier performance management. Companies that implement these long-term strategies gain a competitive edge through greater efficiency, stronger supplier relationships, and better use of capital.

Tools like Cflow play a vital role in making these goals achievable. By automating manual workflows, improving data accuracy, and ensuring compliance, Cflow enables procurement leaders to reduce costs systematically and focus on value-generating activities.

As procurement continues to evolve, those who prioritize cost visibility and digital transformation will be better positioned to scale operations, drive profitability, and support business growth.

Ready to take control of your procurement costs? Start your free trial of Cflow and experience the future of cost-efficient procurement.

FAQs

1. What are procurement costs?

Procurement costs refer to all expenses incurred in acquiring goods or services, including both direct costs (purchase price) and indirect costs (admin, processing, logistics).

2. How can businesses reduce procurement costs?

Businesses can reduce costs by centralizing procurement, using automation tools, streamlining vendors, and analyzing spend data to identify inefficiencies.

3. What is the difference between direct and indirect procurement costs?

Direct costs relate to the actual purchase of goods or services, while indirect costs involve supporting processes like approvals, training, and contract management.

4. Why is procurement cost analysis important?

It helps identify areas of waste, improve supplier selection, and align procurement with financial goals.

5. How does Cflow help in reducing procurement costs?

Cflow automates workflows, improves visibility, and reduces manual effort, cutting down on administrative expenses and accelerating procurement cycles.

What should you do next?

Thanks for reading till the end. Here are 3 ways we can help you automate your business:

Do better workflow automation with Cflow

Create workflows with multiple steps, parallel reviewals. auto approvals, public forms, etc. to save time and cost.

Talk to a workflow expert

Get a 30-min. free consultation with our Workflow expert to optimize your daily tasks.

Get smarter with our workflow resources

Explore our workflow automation blogs, ebooks, and other resources to master workflow automation.

Get Your Workflows Automated for Free!

By submitting this form, you agree to our terms of service and privacy policy.

document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() );