- Cflow

- Production Process Update Automation

Production Process Update Automation

Clow Team

The Production Process Update Process ensures that any changes to manufacturing procedures, equipment settings, quality checks, or production parameters are properly documented, reviewed, and approved before implementation. Without automation, updates are scattered across spreadsheets, emails, or undocumented operator notes, leading to inconsistencies, delays, and safety risks.

Manual coordination across Operations, Quality Control, Engineering, and Compliance teams results in slow reviews, version conflicts, and process drift. Cflow automates the Production Process Update Workflow, ensuring structured change management, compliance, and timely execution on the shop floor.

What Is Production Process Update Process?

The Production Process Update Process manages how changes to production methods—such as work instructions, SOPs, machine configurations, or inspection protocols—are reviewed, approved, and communicated across teams.

Think of it as a version-controlled safety net. Without it, unapproved changes can cause quality deviations, equipment damage, or regulatory violations. Automation ensures that updates go through proper channels, with full traceability and stakeholder alignment.

Studies show that organizations using automated process change control reduce production errors by 35% and shorten change approval cycles by up to 50%.

Why This Process Is Critical for Operations Teams

Consistency & Quality Control

Regulatory Compliance

Cross-Functional Alignment

Audit Trail & Change History

Key Benefits of Automating Production Process Updates with Cflow

- Centralized Change Request Dashboard: Cflow provides a single portal where managers can track all open, pending, and completed process updates.This prevents unauthorized changes and supports organized process governance.

- Multi-Departmental Approval Routing: Engineering, Quality, and Compliance reviewers are automatically notified and assigned based on update type. No process change is implemented until all sign-offs are completed.

- Dynamic Forms with Conditional Fields: Process update requests dynamically, and adjust based on the nature of the change. e.g., equipment, method, or material. This minimizes errors and ensures reviewers receive only relevant information.

- Document Version Control: Cflow integrates with document repositories to upload and track updated SOPs, process sheets, or work instructions. Previous versions are archived automatically for audits or rollback scenarios.

- Automated Notifications & Escalations: Reminders and escalation rules ensure no task gets delayed. Reviewers receive personalized notifications with due dates and comments, improving accountability across departments.

- Real-Time Visibility from Mobile: Supervisors and approvers can review and approve process changes directly from mobile devices, even on the shop floor. This flexibility speeds up decision-making during urgent manufacturing adjustments.

Get the best value for money with Cflow

User Roles & Permissions

Process Owner

- Responsibilities: Initiate change, complete form, and upload updated documentation

- Cflow Permission Level: Submit

- Mapping: “Production Team” group

Engineering Reviewer

- Responsibilities: Validate technical feasibility and equipment compatibility

- Cflow Permission Level: Approve/Reject

- Mapping: “Engineering Team” group

Quality Control Reviewer

- Responsibilities: Evaluate process impact on product quality and inspection standards

- Cflow Permission Level: Approve/Reject

- Mapping: “Quality Team” group

Compliance Officer

- Responsibilities: Ensure updated process complies with regulatory and internal SOPs

- Cflow Permission Level: Task Owner

- Mapping: “Compliance Team” group

Plant Manager / Director

- Responsibilities: Final approval for critical or high-risk updates

- Cflow Permission Level: Approve

- Mapping: “Leadership” group

Audit Reviewer

- Responsibilities: Access archived update records for compliance checks

- Cflow Permission Level: View Only

- Mapping: “Audit” group

Discover why teams choose Cflow

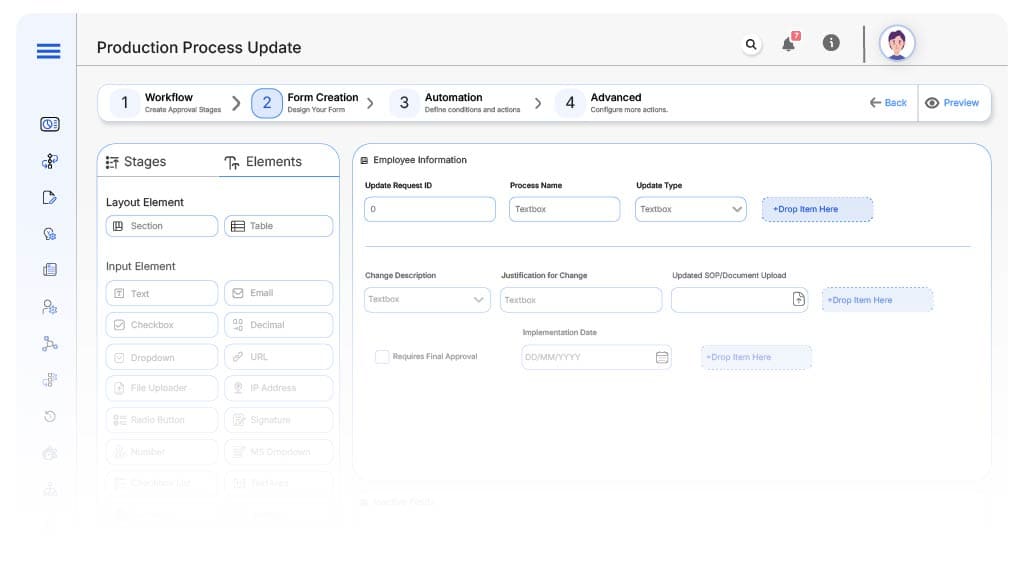

Form Design & Field Definitions

Field Label: Update Request ID

- Type: Autonumber

- Auto-Populate: On submission

Field Label: Process Name

- Type: Text (Read-only)

- Auto-Populate: Pulled from user profile.

Field Label: Update Type

- Type: Dropdown (Method Change, Equipment Change, Parameter Change)

- Logic/Rules: Triggers different routing logic

Field Label: Change Description

- Type: Long Text

- Logic/Rules: Required

Field Label: Justification for Change

- Type: Text Area

- Logic/Rules: Required before routing

Field Label: Updated SOP/Document Upload

- Type: File Upload

- Logic/Rules: Required for Compliance sign-off

Field Label: Requires Final Approval

- Type: Checkbox

- Logic/Rules: If checked → Route to Plant Manager

Field Label: Implementation Date

- Type: Date Picker

- Logic/Rules: Must be within the current month

Field Label: Quality Impact Assessment

- Type: Text Area

- Logic/Rules: Required for Quality Reviewer

Field Label: Approval Confirmation

- Type: Checkbox

- Logic/Rules: Required for process closure

Transform your Workflow with AI fusion

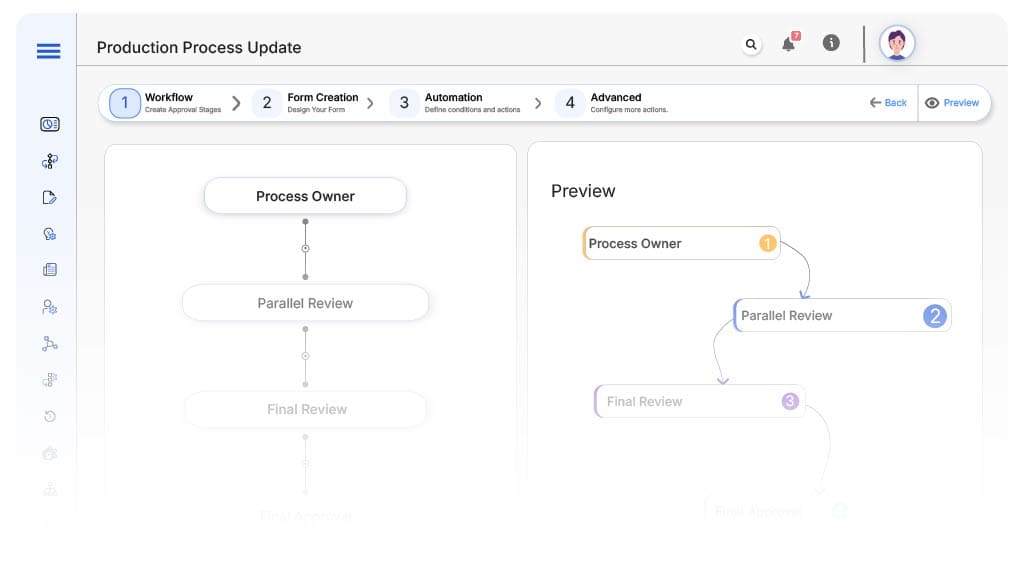

Approval Flow & Routing Logic

Submission → Process Owner

- Status Name: Pending Change Initiation

- Notification Template: “New process update request submitted. Please complete details and upload documents.”

- On Approve: Routes to Engineering, Quality, and Compliance reviewers in parallel

Engineering + Quality + Compliance → Parallel Review

- Status Name: Pending Cross-Functional Review

- Notification Template: “Process update for {Process Name} requires your review.”

- On Approve: If Final Approval is required → Route to Plant Manager

- Escalation: Reminder after 2 days

Plant Manager → Final Review

- Status Name: Pending IT Review

- Notification Template: “Hi IT, please review and approve the equipment request for {Employee}.”

- On Approve: Routes to Procurement.

- Escalation: Reminder after 2 days.

Process Owner → Confirmation

- Status Name: Pending Confirmation & Archival

- Notification Template: “All approvals complete. Confirm process update and archive.”

- On Approve: Moves to Final Archive

Final → Process Update Complete

- Status Name: Update Complete

- Notification Template: “Process update for {Process Name} has been finalized and archived successfully.”

- On Complete: Record archived and audit trail stored

Transform your AI-powered approvals

Implementation Steps in Cflow

Create a new workflow

Design the form

Set up User Roles/Groups

Build process flow

Configure notifications

Set conditional logic

Save and publish

Test flow

Launch live

Example Journey: Packaging Line Speed Change

The Production Team submits a request to increase conveyor speed on the packaging line. Engineering confirms compatibility, Quality assesses potential inspection changes, and Compliance reviews updated SOPs. Since it’s a high-impact change, it routes to the Plant Manager for final approval. Once signed off, the new SOP is archived, and the change is communicated across production teams with full traceability.

FAQ's

Unleash the full potential of your AI-powered Workflow