Comprehensive Guide to Procurement Risk Management

Cflow Team

Share this Content

Key takeaways

- Procurement risk management helps organizations identify, assess, and mitigate potential risks in sourcing and purchasing processes.

- Common procurement risks include supply chain disruptions, compliance violations, vendor reliability issues, and financial uncertainties.

- Effective procurement risk assessment ensures strategic sourcing decisions and reduces operational vulnerabilities.

- Supplier risk management plays a critical role in preventing quality issues and delivery delays.

- Implementing procurement risk mitigation strategies improves efficiency, transparency, and long-term supplier relationships.

Procurement risk management is the structured process of identifying, evaluating, and controlling risks that can disrupt purchasing and supply chain operations. It is a crucial component of procurement governance that ensures goods and services are acquired in a cost-effective, compliant, and sustainable way. Risks in procurement can arise from multiple factors, including supplier insolvency, quality failures, contract disputes, or sudden geopolitical changes affecting trade.

For organizations, managing procurement risk is not just a reactive process but a proactive approach to safeguarding operational continuity and profitability. It requires integrating procurement risk analysis into decision-making, involving cross-functional teams, and using reliable procurement risk frameworks to guide strategic actions. This blog explores the types of procurement risks, the processes to assess them, and the strategies to mitigate their impact effectively.

Table of Contents

Understanding Procurement Risk Assessment

Procurement risk assessment involves systematically identifying potential risks in the procurement process, evaluating their likelihood and potential impact, and prioritizing them for mitigation. The process begins by mapping procurement workflows to detect vulnerable points, such as reliance on single suppliers, ambiguous contract terms, or lack of compliance monitoring.

Quantitative tools like risk scoring models and qualitative approaches like supplier audits are often used to conduct this assessment. Procurement process risk assessment also requires input from stakeholders across departments to capture operational, financial, and reputational risks. The goal is to have a clear view of threats before they escalate into disruptions.

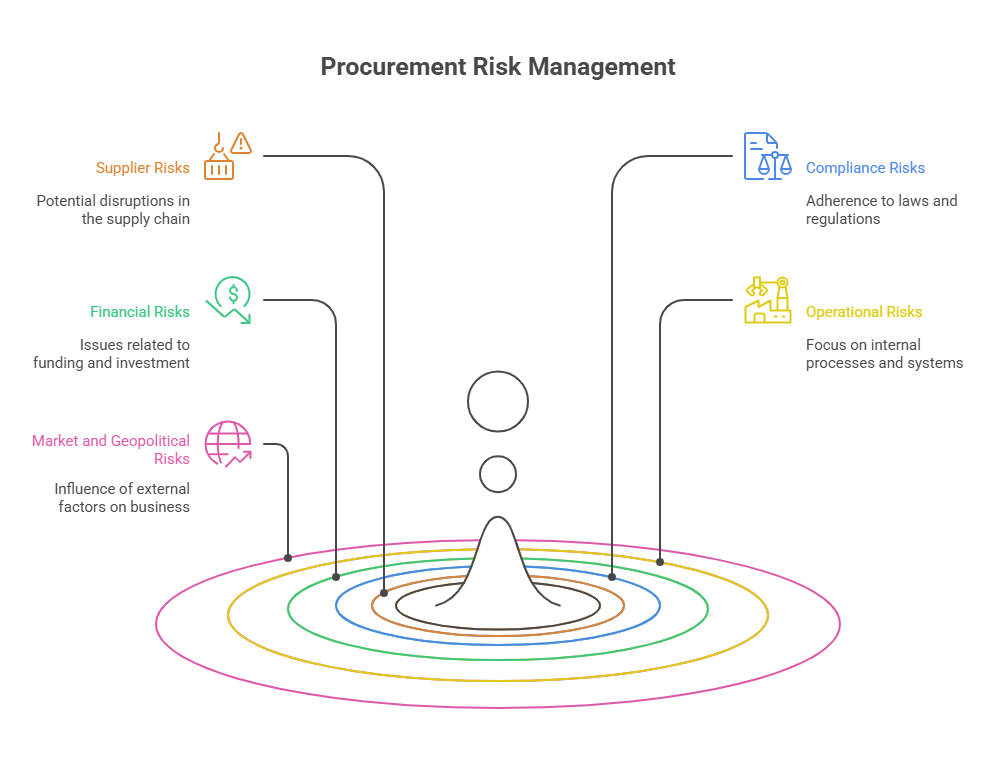

Common Types of Procurement Risks

Procurement risks can occur at any stage of the purchasing process, from sourcing to contract management and delivery. Understanding these risks in detail enables organizations to implement effective prevention and mitigation measures. Below are the main categories of procurement risks and their implications:

Supplier Risks

These risks arise from issues within the supplier’s operations that directly impact the buyer. They can include financial instability, poor manufacturing practices, or a lack of capacity to meet demand. Supplier insolvency or bankruptcy can abruptly halt deliveries, while quality failures may lead to defective goods, product recalls, or customer dissatisfaction. Reliance on a single supplier magnifies this risk, especially in critical supply categories.

Example: A manufacturer depending on a single overseas supplier may face severe delays if that supplier’s region experiences political unrest or natural disasters.

Compliance Risks

Procurement compliance risk refers to the possibility of violating laws, regulations, or internal policies. These can include breaches of labor laws, environmental regulations, anti-bribery laws, or trade restrictions. Non-compliance can lead to fines, legal disputes, or reputational damage. In regulated industries such as pharmaceuticals or defense, even small lapses in compliance can have severe consequences.

Example: Sourcing from a supplier that uses child labor can result in legal penalties and loss of customer trust.

Financial Risks

These risks are linked to budget overruns, currency fluctuations, unexpected price increases, or payment defaults. Without proper contract clauses or financial planning, organizations can face cost escalations that erode profit margins. Unstable market conditions or inflation can also trigger sudden spikes in procurement costs.

Example: An import-dependent business may face higher costs if exchange rates shift unfavorably after a contract is signed.

Operational Risks

Operational risks occur when internal procurement processes fail due to poor planning, lack of skilled personnel, or inefficient technology systems. These risks often result in delays, inaccurate demand forecasting, and poor inventory management. They may also arise from weak procurement governance and risk management frameworks.

Example: A procurement team without proper digital tools may lose track of purchase orders, causing delays and duplication of work.

Quality Risks

Quality risks emerge when purchased goods or services fail to meet agreed standards or specifications. This can occur due to insufficient supplier vetting, lack of quality assurance checks, or unclear contract requirements. Poor quality can lead to rework, wastage, and negative customer experiences.

Example: A construction project may be delayed if materials supplied do not meet safety or durability standards.

Market and Geopolitical Risks

These risks stem from external market forces and political events that disrupt procurement activities. Changes in trade policies, tariffs, sanctions, or geopolitical conflicts can make sourcing from certain regions difficult or impossible. Additionally, market volatility in raw material prices can make budgeting unpredictable.

Example: Trade restrictions on specific countries can abruptly end long-standing supplier relationships.

Technology Risks

In an increasingly digital procurement landscape, technology failures pose a significant risk. Cybersecurity breaches, software malfunctions, or data loss can compromise procurement data and disrupt supplier communications. Dependence on outdated or incompatible systems can also hinder procurement efficiency.

Example: A cyberattack on a procurement software platform can expose sensitive contract and supplier data.

Sustainability and Ethical Sourcing Risks

These risks relate to the environmental and social impact of procurement decisions. Failing to adopt sustainable and ethical sourcing practices can lead to reputational harm, regulatory scrutiny, and loss of market share. Many organizations now require suppliers to adhere to sustainability commitments as part of contract risk management in procurement.

Example: Partnering with suppliers who cause significant environmental damage can alienate stakeholders and customers.

By clearly identifying these procurement risks, organizations can develop targeted procurement risk mitigation strategies and ensure that procurement risk assessment processes address each risk type comprehensively.

Procurement Risk Mitigation Strategies

Effective procurement risk management is not just about identifying risks; it is about creating and implementing targeted actions that reduce the likelihood of these risks occurring or minimize their impact when they do occur. Below are key procurement risk mitigation strategies aligned with common risk types:

1. Mitigating Supplier Risks

- Diversify the supplier base: Avoid over-reliance on a single vendor by sourcing from multiple suppliers across different regions.

- Conduct regular supplier audits: Evaluate suppliers on quality, financial health, capacity, and compliance.

- Create supplier scorecards: Track and compare vendor performance using measurable criteria like on-time delivery, defect rates, and responsiveness.

- Establish contingency agreements: Have secondary suppliers ready to step in if the primary supplier fails.

2. Mitigating Compliance Risks

- Implement robust procurement governance: Ensure all processes adhere to internal policies and external regulations.

- Use compliance monitoring tools: Automate checks for sanctions, legal violations, and regulatory requirements.

- Conduct due diligence on suppliers: Verify certifications, licenses, and ethical sourcing practices before onboarding vendors.

- Train procurement staff: Regular training on industry-specific laws and international trade compliance.

3. Mitigating Financial Risks

- Use hedging for currency fluctuations: Lock in exchange rates for international contracts to protect against volatility.

- Negotiate price adjustment clauses: Include terms in contracts to handle market price fluctuations fairly.

- Set strict budget controls: Implement approval workflows for purchases above defined thresholds.

- Evaluate supplier payment terms: Balance cash flow needs with favorable payment schedules.

4. Mitigating Operational Risks

- Adopt procurement automation systems: Replace manual processes with technology to reduce human error.

- Standardize procurement workflows: Clearly define each step in the purchasing process to ensure consistency.

- Train procurement teams: Upskill staff in contract management, negotiation, and procurement risk assessment.

- Conduct scenario planning: Prepare contingency plans for supply chain disruptions.

5. Mitigating Quality Risks

- Define quality standards in contracts: Specify exact requirements for materials, performance, and tolerances.

- Inspect goods before acceptance: Use third-party quality assurance for high-value or critical items.

- Set penalties for non-compliance: Include clauses for replacements, refunds, or damages if quality standards are not met.

- Collaborate with suppliers on improvement plans: Work jointly to enhance production quality.

6. Mitigating Market and Geopolitical Risks

- Monitor geopolitical developments: Track political, economic, and trade policy changes in sourcing regions.

- Source from politically stable regions: Reduce exposure to conflict-prone areas.

- Stock critical materials: Build safety inventory to withstand supply delays.

- Establish multi-region supply networks: Balance sourcing across diverse geographic areas.

7. Mitigating Technology Risks

- Invest in secure procurement platforms: Use software with strong encryption and access controls.

- Perform regular system backups: Protect procurement and supplier data from loss or corruption.

- Update systems regularly: Ensure software and hardware are up to date with security patches.

- Have an IT disaster recovery plan: Maintain a roadmap for restoring procurement operations quickly after tech failures.

8. Mitigating Sustainability and Ethical Sourcing Risks

- Adopt sustainable procurement policies: Make environmental and social impact part of vendor selection criteria.

- Audit supplier practices: Ensure vendors meet ethical labor, safety, and environmental standards.

- Engage in supplier development programs: Help suppliers meet sustainability expectations.

- Use traceability tools: Track product origins to verify sustainable and ethical sourcing.

By linking each risk type to specific mitigation actions, organizations can create a comprehensive procurement risk framework that improves resilience, strengthens supplier relationships, and ensures operational continuity. Implementing these procurement risk control measures requires commitment from leadership, investment in technology, and a culture of continuous improvement.

Supplier and Vendor Risk Management

Supplier risk management is a critical element of procurement risk management. It focuses on assessing and managing the reliability, quality, and compliance of vendors throughout the procurement lifecycle. This includes pre-qualification checks, reviewing financial stability, evaluating past performance, and ensuring adherence to ethical sourcing standards.

Vendor risk management in procurement also involves establishing clear service-level agreements, maintaining open communication, and continuously monitoring performance metrics. Proactive supplier management prevents costly procurement disruptions and supports long-term strategic relationships.

Procurement Risk Framework and Governance

A procurement risk framework is the structured methodology that organizations use to identify, evaluate, mitigate, and monitor risks across the procurement lifecycle. It serves as the blueprint for consistent and transparent decision-making, ensuring that procurement teams manage risks systematically rather than reactively. Procurement governance complements this framework by establishing clear policies, controls, and accountability measures that align with organizational objectives and regulatory requirements. Together, they form the foundation for effective procurement risk management.

Core Components of a Procurement Risk Framework

An effective procurement risk framework typically includes:

Risk Identification Guidelines: A standardized approach for identifying risks, such as supplier instability, compliance breaches, financial volatility, or operational inefficiencies. This step ensures no critical risk area is overlooked during procurement risk assessment.

Risk Categorization and Prioritization: Classifying risks into categories like operational, financial, market, compliance, and reputational risks, and ranking them based on likelihood and impact. This helps procurement teams focus on the most significant threats.

Assessment Tools and Metrics: Quantitative measures like risk scoring models and qualitative assessments, such as supplier audits or interviews. These tools provide a consistent way to evaluate procurement risks across projects and suppliers.

Mitigation Planning: Pre-defined procurement risk mitigation strategies tailored to each risk category, from supplier diversification to implementing advanced compliance checks.

Monitoring and Reporting Mechanisms: Real-time dashboards, supplier scorecards, and periodic reviews to track emerging risks and assess the effectiveness of control measures.

Role of Procurement Governance in Risk Management

Procurement governance establishes the rules, roles, and responsibilities that guide procurement activities. It ensures that procurement processes are not only efficient but also compliant with legal, ethical, and sustainability standards. Strong governance includes:

Clear Policy Frameworks: Documented procurement policies covering vendor selection, contract management, compliance monitoring, and supplier relationship management.

Defined Accountability Structures: Assigning clear ownership for risk management tasks, from procurement officers to senior leadership.

Approval and Escalation Procedures: Structured workflows for approving high-value or high-risk procurements and escalating issues that require senior intervention.

Internal Controls and Audit Trails: Mechanisms to detect procurement fraud, prevent unauthorized spending, and maintain transparency through detailed records.

Alignment with Organizational Goals: Ensuring that procurement strategies contribute to broader business objectives, such as cost efficiency, sustainability, and innovation.

Integrating the Framework and Governance for Maximum Impact

When a procurement risk framework is fully embedded within strong governance structures, risk management becomes an integral part of daily procurement operations rather than an isolated activity. This integration allows for:

Consistency: Every procurement decision is made within a standard risk evaluation process.

Transparency: Stakeholders at all levels have visibility into procurement risks and the measures in place to address them.

Compliance Assurance: Regular monitoring and adherence to policies reduce the likelihood of legal or regulatory breaches.

Proactive Risk Response: Early detection of risks enables organizations to act before disruptions escalate.

A well-structured procurement governance and risk management system is not static; it must evolve with changes in market conditions, technology, regulations, and business priorities. Organizations that regularly review and update their procurement risk framework can maintain resilience, strengthen supplier relationships, and safeguard their reputation in competitive markets.

End-to-end workflow automation

Build fully-customizable, no code process workflows in a jiffy.

Role of Procurement Risk Monitoring and Control Measures

Procurement risk monitoring and control measures are essential for ensuring that identified risks remain under control throughout the procurement lifecycle. Risk monitoring is a continuous process; it does not end after initial risk assessment. Instead, it involves tracking key risk indicators, supplier performance, compliance status, and market conditions to detect early warning signs of potential disruptions. Control measures, on the other hand, are the actions and safeguards put in place to reduce the likelihood of risks occurring or to minimize their impact if they do.

Importance of Continuous Risk Monitoring

Ongoing monitoring ensures that procurement teams can respond proactively rather than reactively. Markets, regulations, and supplier conditions can change rapidly, and without proper tracking mechanisms, even well-managed procurement processes can be exposed to sudden risks. Effective procurement risk monitoring provides:

- Early Detection of Problems: Identifying deviations in supplier performance, such as delayed shipments or quality issues, before they escalate into major disruptions.

- Data-Driven Decision Making: Using supplier scorecards, risk dashboards, and compliance reports to make informed procurement decisions.

- Alignment with Compliance Requirements: Ensuring that all suppliers and processes adhere to applicable legal, contractual, and ethical standards.

- Real-Time Adaptability: Adjusting procurement strategies quickly in response to changing risk conditions, such as geopolitical events or commodity price fluctuations.

Key Procurement Risk Monitoring Tools and Practices

- Supplier Performance Dashboards: Track delivery times, defect rates, and service responsiveness.

- Automated Compliance Alerts: Notify procurement teams of changes in supplier certifications, regulatory requirements, or sanctions lists.

- Market Intelligence Systems: Monitor commodity prices, geopolitical developments, and emerging risks in supplier regions.

- Regular Audits and Reviews: Conduct periodic supplier and internal process audits to uncover hidden vulnerabilities.

Role of Control Measures in Risk Mitigation

Control measures are proactive safeguards that prevent risks from materializing or reduce their impact. These measures can be both procedural and technological:

- Contractual Safeguards: Including penalty clauses, quality guarantees, and service-level agreements to ensure supplier accountability.

- Segregation of Duties: Assigning different individuals to request, approve, and process purchases to prevent procurement fraud.

- Automated Workflow Approvals: Using procurement software to enforce approval thresholds and ensure purchases are vetted before commitment.

- Inventory and Safety Stock Controls: Maintaining buffer stock for critical materials to protect against supply chain disruptions.

- Scenario Testing and Simulation: Running “what-if” analyses to see how procurement processes would handle various risk scenarios.

Integration of Monitoring and Control

Monitoring and control measures should work hand-in-hand. For example, if a supplier’s on-time delivery rate drops below a set threshold, automated monitoring tools should trigger alerts that lead to specific control actions, such as engaging backup suppliers or revising delivery schedules. The integration ensures that procurement risk management is dynamic, responsive, and aligned with both operational needs and strategic goals.

Benefits of Strong Risk Monitoring and Control Systems

- Reduced Procurement Disruptions: Early detection and rapid intervention help maintain supply chain stability.

- Enhanced Supplier Relationships: Transparent monitoring encourages collaboration with vendors to address performance issues.

- Improved Compliance: Consistent oversight reduces the risk of legal or regulatory violations.

- Better Resource Allocation: Focuses time and resources on managing the most critical risks rather than spreading attention thinly across all areas.

In essence, procurement risk monitoring and control measures form the operational backbone of procurement risk management. Without them, even the most comprehensive procurement risk framework would be incomplete, leaving organizations exposed to avoidable disruptions and losses.

Strategic Procurement Risk Management for Long-Term Success

Strategic procurement risk management goes beyond immediate risk avoidance. It aligns procurement decisions with long-term business resilience goals. This approach involves building strong supplier partnerships, investing in supply chain diversification, and leveraging advanced analytics to anticipate risks before they materialize.

Organizations adopting a strategic approach to risk management in purchasing can optimize costs, ensure business continuity, and strengthen market competitiveness. The integration of supply chain risk management in procurement ensures that resilience is embedded across the entire sourcing and delivery ecosystem.

Conclusion

Procurement risk management is not a one-time initiative but a continuous, strategic function that protects organizations from disruptions, financial losses, and compliance failures. By integrating procurement risk assessment, supplier risk management, and procurement risk mitigation strategies into daily operations, businesses can build a resilient supply chain and improve decision-making.

A well-structured procurement risk framework and consistent procurement risk monitoring empower organizations to address challenges proactively. In an era of unpredictable markets, organizations that prioritize procurement risk management will gain a competitive advantage while safeguarding operational continuity. Eliminating redundant steps from procurement workflows can mitigate the risk considerably. Partner with Cflow to automate your procurement workflows and ensure effective procurement risk management. Sign up to know more.

FAQs

What is procurement risk management?

It is the process of identifying, assessing, and mitigating risks in procurement to ensure smooth supply chain operations and compliance.

What are common procurement risks?

They include supplier failures, compliance breaches, financial losses, operational inefficiencies, and market disruptions.

How can supplier risk be reduced in procurement?

By diversifying suppliers, conducting regular audits, establishing strong contracts, and monitoring vendor performance continuously.

What tools help in procurement risk management?

Procurement software, supplier scorecards, compliance tracking systems, and risk dashboards are commonly used tools.

Why is strategic procurement risk management important?

It ensures long-term resilience, reduces cost volatility, improves supplier relationships, and aligns procurement with business goals.

What should you do next?

Thanks for reading till the end. Here are 3 ways we can help you automate your business:

Do better workflow automation with Cflow

Create workflows with multiple steps, parallel reviewals. auto approvals, public forms, etc. to save time and cost.

Talk to a workflow expert

Get a 30-min. free consultation with our Workflow expert to optimize your daily tasks.

Get smarter with our workflow resources

Explore our workflow automation blogs, ebooks, and other resources to master workflow automation.